The Potential of Guayule

Guayule, pronounced why-YOU-lee, provides an alternative and sustainable commercial source of rubber for breakthrough biomaterials. Since 1999 American BioRubber has led the industry in developing guayule crops to create sustainable rubber products.

About the Guayule Plant

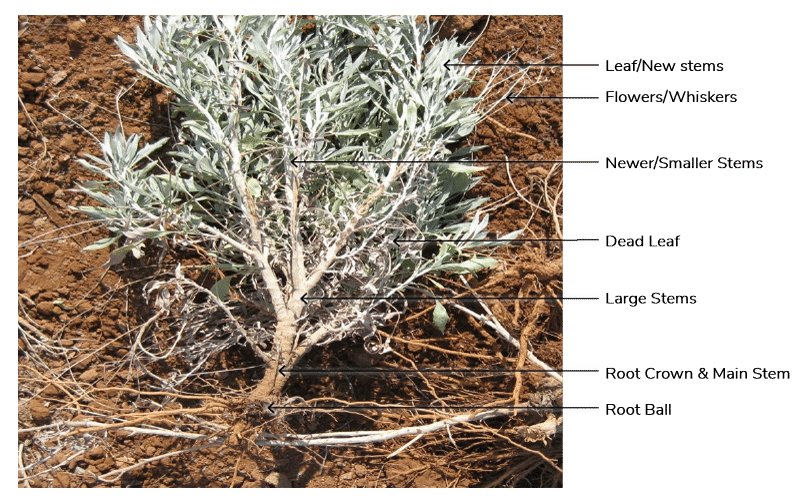

Guayule is a perennial, non-food crop

9-17 months to first harvest, then annual harvests (variety dependent)

Grows successfully on marginal land

Low water usage compared to cotton/alfalfa (~6 acre feet/year)

18+ tons of residual dry biomass/acre

Tremendous upside through agroscience development activities

Aligns with existing agronomic practices

High output = 1 ton/rubber/acre, already equal to SE Asian rubber plantations (per acre basis)

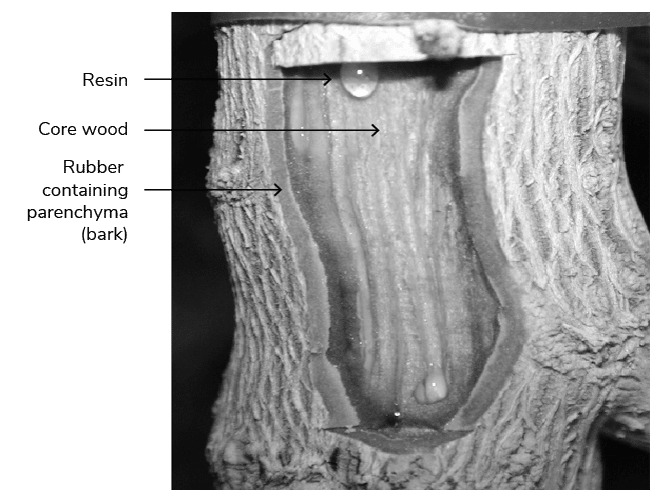

Guayule (Parthenium argentatum), a woody, evergreen shrub that originated in the deserts of the U.S. Southwest and Mexico. Is the only species other than the Brazilian rubber tree (Hevea brasiliensis) that is used commercially for the production of rubber.

Amercian Biorubber and Guayule

American BioRubber was the first company to developed multiple processing methods for the extraction and refinement of guayule seed oil, a unique oil high in Linolenic Acid which is an essential fatty acid belonging to the omega-3 fatty acids group.